Consent Manager Tag v2.0 (for TCF 2.0) -->

Farnell PDF

The power demands of data centers require memory ... - Crucial

The power demands of data centers require memory ... - Crucial

The power demands of data centers require memory ... - Crucial

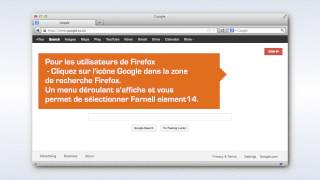

- Revenir à l'accueil

Farnell Element 14 :

See the trailer for the next exciting episode of The Ben Heck show. Check back on Friday to be among the first to see the exclusive full show on element…

Connect your Raspberry Pi to a breadboard, download some code and create a push-button audio play project.

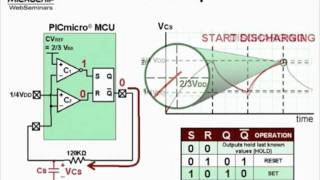

Puce électronique / Microchip :

Sans fil - Wireless :

Texas instrument :

Ordinateurs :

Logiciels :

Tutoriels :

Autres documentations :

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CLRC632-NXP-..> 20-Dec-2014 10:22 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-7491181012-O..> 20-Dec-2014 10:22 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC4350-30-2..> 20-Dec-2014 10:21 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC178x-7x-N..> 20-Dec-2014 10:21 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Data-Sheet-J..> 20-Dec-2014 10:21 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC81xM-NXP-..> 20-Dec-2014 10:20 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Data-Sheet-J..> 20-Dec-2014 10:20 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SL3S1003_101..> 20-Dec-2014 10:06 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NT3H1101-NT3..> 20-Dec-2014 10:06 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC1769-68-6..> 20-Dec-2014 10:06 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SL3S1203_121..> 20-Dec-2014 10:01 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PN512-NXP-Se..> 20-Dec-2014 10:01 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MMBZxVCL-MMB..> 20-Dec-2014 09:53 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Datasheet-NX..> 20-Dec-2014 09:52 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-IP4251_52_53..> 20-Dec-2014 09:51 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BC846DS2-NXP..> 20-Dec-2014 09:48 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BAT54J-Schot..> 20-Dec-2014 09:47 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PMEG3010EP-N..> 20-Dec-2014 09:47 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AVR172-Senso..> 20-Dec-2014 09:47 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PBSS5320X-NX..> 20-Dec-2014 09:47 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ATtiny2313-A..> 20-Dec-2014 09:47 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SG2525A-SG35..> 20-Dec-2014 09:39 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PMBT3906-PNP..> 20-Dec-2014 09:39 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PDTB123TT-NX..> 20-Dec-2014 09:39 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PIC12F529T39..> 20-Dec-2014 09:39 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PSMN011-80YS..> 20-Dec-2014 09:39 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PESD5V0F1BL-..> 20-Dec-2014 09:39 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MB85RS128B-F..> 20-Dec-2014 09:38 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SMAJ-STMicro..> 13-Oct-2014 07:07 734K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L6562-STMicr..> 13-Oct-2014 07:07 754K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM139-LM239-..> 13-Oct-2014 07:07 771K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L4978-STMicr..> 13-Oct-2014 07:07 783K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ST1S10PHR-ST..> 13-Oct-2014 07:06 820K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TIP41C-TIP42..> 13-Oct-2014 07:06 829K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MC34063ABD-T..> 13-Oct-2014 07:06 844K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ESM6045DV-ST..> 13-Oct-2014 07:06 850K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TIP102-TIP10..> 13-Oct-2014 07:06 853K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ST3232B-ST32..> 13-Oct-2014 07:06 867K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STM32F030x4-..> 13-Oct-2014 07:06 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STM32F103x8-..> 13-Oct-2014 07:06 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STM32F405xx-..> 13-Oct-2014 07:05 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STM32F205xx-..> 13-Oct-2014 07:05 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STP16NF06L-n..> 13-Oct-2014 07:05 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STP80NF55L-0..> 13-Oct-2014 07:05 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM217-LM317-..> 13-Oct-2014 07:04 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM2904-LM290..> 13-Oct-2014 07:04 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L78-Positive..> 13-Oct-2014 07:04 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-VND920P-E-ST..> 13-Oct-2014 07:04 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM350-STMicr..> 13-Oct-2014 07:03 1.8M

![[ ]](http://www.audentia-gestion.fr/icons/layout.gif)

Smart_street_lightin..> 13-Oct-2014 07:03 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Smart-street..> 13-Oct-2014 07:02 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ULN2001-ULN2..> 13-Oct-2014 07:02 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ULQ2001-ULQ2..> 13-Oct-2014 07:02 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L6384E-STMic..> 13-Oct-2014 07:02 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AN2794-Appli..> 13-Oct-2014 07:01 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STEVAL-TDR02..> 13-Oct-2014 07:01 960K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TL084-TL084A..> 11-Oct-2014 15:54 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TDA7296-STMi..> 11-Oct-2014 15:54 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L78-STMicroe..> 11-Oct-2014 15:49 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM158-LM258-..> 11-Oct-2014 15:49 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LF351-STMicr..> 11-Oct-2014 15:49 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L293B-STMicr..> 11-Oct-2014 15:49 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NE556-SA556-..> 11-Oct-2014 15:48 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SO967460-PDF..> 11-Oct-2014 12:05 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Everything-Y..> 11-Oct-2014 12:05 1.5M

![[ ]](http://www.audentia-gestion.fr/icons/unknown.gif)

cookiechoices.js 27-Sep-2014 12:40 6.0K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ULN2803A-Rev..> 09-Sep-2014 19:26 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Convo..> 09-Sep-2014 08:26 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Convo..> 09-Sep-2014 08:25 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Convo..> 09-Sep-2014 08:25 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-ADMC4..> 09-Sep-2014 08:23 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Wi-Fi..> 09-Sep-2014 08:23 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-ADMC2..> 09-Sep-2014 08:21 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-ADC-S..> 09-Sep-2014 08:21 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Visua..> 09-Sep-2014 08:18 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-ANF32..> 09-Sep-2014 08:18 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Compensating..> 09-Sep-2014 08:16 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Compensating..> 09-Sep-2014 08:16 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM7805-Fairc..> 09-Sep-2014 08:13 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD620-Rev-H-..> 09-Sep-2014 08:13 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Datasheet-FT..> 09-Sep-2014 08:10 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MAX4661-MAX4..> 09-Sep-2014 08:10 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-OPA627-Texas..> 09-Sep-2014 08:08 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-REF19x-Serie..> 09-Sep-2014 08:08 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Data-Sheet-M..> 09-Sep-2014 08:05 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Digit..> 08-Sep-2014 18:03 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Digit..> 08-Sep-2014 18:02 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Basic..> 08-Sep-2014 17:49 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD9833-Rev-E..> 08-Sep-2014 17:49 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-The-Discrete..> 08-Sep-2014 17:44 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Electronique-Basic-o..> 08-Sep-2014 17:43 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-AN300..> 08-Sep-2014 17:42 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-The-C..> 08-Sep-2014 17:41 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Intro..> 08-Sep-2014 17:39 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Compl..> 08-Sep-2014 17:38 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Analog-Devices-Gloss..> 08-Sep-2014 17:36 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ADuM1300-ADu..> 08-Sep-2014 08:11 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD586BRZ-Ana..> 08-Sep-2014 08:09 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ADuM1200-ADu..> 08-Sep-2014 08:09 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NA555-NE555-..> 08-Sep-2014 07:51 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD9834-Rev-D..> 08-Sep-2014 07:32 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MSP430F15x-M..> 08-Sep-2014 07:32 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD736-Rev-I-..> 08-Sep-2014 07:31 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD8307-Data-..> 08-Sep-2014 07:30 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Single-Chip-..> 08-Sep-2014 07:30 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Quadruple-2-..> 08-Sep-2014 07:29 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ADE7758-Rev-..> 08-Sep-2014 07:28 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MAX3221-Rev-..> 08-Sep-2014 07:28 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-USB-to-Seria..> 08-Sep-2014 07:27 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD8313-Analo..> 08-Sep-2014 07:26 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SN54HC164-SN..> 08-Sep-2014 07:25 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD8310-Analo..> 08-Sep-2014 07:24 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD8361-Rev-D..> 08-Sep-2014 07:23 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-2N3906-Fairc..> 08-Sep-2014 07:22 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD584-Rev-C-..> 08-Sep-2014 07:20 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ADE7753-Rev-..> 08-Sep-2014 07:20 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TLV320AIC23B..> 08-Sep-2014 07:18 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STM32F405xxS..> 27-Aug-2014 18:27 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-fx-3650P-fx-..> 29-Jul-2014 10:42 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MSP430-Hardw..> 29-Jul-2014 10:36 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM324-Texas-..> 29-Jul-2014 10:32 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM386-Low-Vo..> 29-Jul-2014 10:32 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NE5532-Texas..> 29-Jul-2014 10:32 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Hex-Inverter..> 29-Jul-2014 10:31 875K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AT90USBKey-H..> 29-Jul-2014 10:31 902K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AT89C5131-Ha..> 29-Jul-2014 10:31 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MSP-EXP430F5..> 29-Jul-2014 10:31 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Explorer-16-..> 29-Jul-2014 10:31 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TMP006EVM-Us..> 29-Jul-2014 10:30 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Gertboard-Us..> 29-Jul-2014 10:30 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LMP91051-Use..> 29-Jul-2014 10:30 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Thermometre-..> 29-Jul-2014 10:30 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-user-manuel-..> 29-Jul-2014 10:29 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TLV320AIC325..> 28-Jul-2014 17:45 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-2-GBPS-Diffe..> 28-Jul-2014 17:42 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LMT88-2.4V-1..> 28-Jul-2014 17:42 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Octal-Genera..> 28-Jul-2014 17:42 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Dual-MOSFET-..> 28-Jul-2014 17:41 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SN54LV4053A-..> 28-Jul-2014 17:20 5.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TAS1020B-USB..> 28-Jul-2014 17:19 6.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TPS40060-Wid..> 28-Jul-2014 17:19 6.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TL082-Wide-B..> 28-Jul-2014 17:16 6.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-RF-short-tra..> 28-Jul-2014 17:16 6.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-maxim-integr..> 28-Jul-2014 17:14 6.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TSV6390-TSV6..> 28-Jul-2014 17:14 6.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Fast-Charge-..> 28-Jul-2014 17:12 6.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NVE-datashee..> 28-Jul-2014 17:12 6.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Excalibur-Hi..> 28-Jul-2014 17:10 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Excalibur-Hi..> 28-Jul-2014 17:10 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-REF102-10V-P..> 28-Jul-2014 17:09 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TMS320F28055..> 28-Jul-2014 17:09 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ULINKpro-Deb..> 25-Jul-2014 12:35 5.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-WIRE-WRAP-50..> 25-Jul-2014 12:34 5.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MICROCHIP-PI..> 25-Jul-2014 12:34 6.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-OMRON-INDUST..> 25-Jul-2014 12:32 6.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-OMRON-INDUST..> 25-Jul-2014 12:31 6.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TYCO-ELECTRO..> 25-Jul-2014 12:30 6.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Power-suppli..> 25-Jul-2014 12:29 7.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Schroff-A108..> 25-Jul-2014 12:27 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Schroff-Main..> 25-Jul-2014 12:26 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Schroff-mult..> 25-Jul-2014 12:26 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Quick-Start-..> 25-Jul-2014 12:25 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PiFace-Digit..> 25-Jul-2014 12:25 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PicoScope-se..> 25-Jul-2014 12:24 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Trust-Digita..> 25-Jul-2014 12:24 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Jeu-multi-la..> 25-Jul-2014 12:23 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PicoScope-42..> 25-Jul-2014 12:23 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LD-WSECO16-P..> 25-Jul-2014 12:22 3.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Circuit-Impr..> 25-Jul-2014 12:22 3.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MULTICOMP-Ra..> 22-Jul-2014 12:57 5.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-RASPBERRY-PI..> 22-Jul-2014 12:35 5.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Dremel-Exper..> 22-Jul-2014 12:34 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-STM32F103x8-..> 22-Jul-2014 12:33 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BD6xxx-PDF.htm 22-Jul-2014 12:33 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L78S-STMicro..> 22-Jul-2014 12:32 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-RaspiCam-Doc..> 22-Jul-2014 12:32 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SB520-SB5100..> 22-Jul-2014 12:32 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-iServer-Micr..> 22-Jul-2014 12:32 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LUMINARY-MIC..> 22-Jul-2014 12:31 3.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TEXAS-INSTRU..> 22-Jul-2014 12:31 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TEXAS-INSTRU..> 22-Jul-2014 12:30 4.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CLASS 1-or-2..> 22-Jul-2014 12:30 4.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TEXAS-INSTRU..> 22-Jul-2014 12:29 4.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Evaluating-t..> 22-Jul-2014 12:28 4.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM3S6952-Mic..> 22-Jul-2014 12:27 5.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Keyboard-Mou..> 22-Jul-2014 12:27 5.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-0050375063-D..> 18-Jul-2014 17:03 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Mini-Fit-Jr-..> 18-Jul-2014 17:03 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-43031-0002-M..> 18-Jul-2014 17:03 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-0433751001-D..> 18-Jul-2014 17:02 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Cube-3D-Prin..> 18-Jul-2014 17:02 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MTX-Compact-..> 18-Jul-2014 17:01 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MTX-3250-MTX..> 18-Jul-2014 17:01 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ATtiny26-L-A..> 18-Jul-2014 17:00 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MCP3421-Micr..> 18-Jul-2014 17:00 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM19-Texas-I..> 18-Jul-2014 17:00 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Data-Sheet-S..> 18-Jul-2014 17:00 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LMH6518-Texa..> 18-Jul-2014 16:59 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD7719-Low-V..> 18-Jul-2014 16:59 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-DAC8143-Data..> 18-Jul-2014 16:59 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BGA7124-400-..> 18-Jul-2014 16:59 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SICK-OPTIC-E..> 18-Jul-2014 16:58 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LT3757-Linea..> 18-Jul-2014 16:58 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LT1961-Linea..> 18-Jul-2014 16:58 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PIC18F2420-2..> 18-Jul-2014 16:57 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-DS3231-DS-PD..> 18-Jul-2014 16:57 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-RDS-80-PDF.htm 18-Jul-2014 16:57 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD8300-Data-..> 18-Jul-2014 16:56 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LT6233-Linea..> 18-Jul-2014 16:56 1.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MAX1365-MAX1..> 18-Jul-2014 16:56 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-XPSAF5130-PD..> 18-Jul-2014 16:56 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-DP83846A-DsP..> 18-Jul-2014 16:55 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SL3ICS1002-1..> 16-Jul-2014 09:05 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MCOC1-Farnel..> 16-Jul-2014 09:04 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SL3S1203_121..> 16-Jul-2014 09:04 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PN512-Full-N..> 16-Jul-2014 09:03 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SL3S4011_402..> 16-Jul-2014 09:03 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC408x-7x 3..> 16-Jul-2014 09:03 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PCF8574-PCF8..> 16-Jul-2014 09:03 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC81xM-32-b..> 16-Jul-2014 09:02 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC1769-68-6..> 16-Jul-2014 09:02 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Download-dat..> 16-Jul-2014 09:02 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC3220-30-4..> 16-Jul-2014 09:02 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LPC11U3x-32-..> 16-Jul-2014 09:01 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Full-Datashe..> 15-Jul-2014 17:08 951K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-pmbta13_pmbt..> 15-Jul-2014 17:06 959K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-EE-SPX303N-4..> 15-Jul-2014 17:06 969K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Datasheet-NX..> 15-Jul-2014 17:06 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Datasheet-Fa..> 15-Jul-2014 17:05 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MIDAS-un-tra..> 15-Jul-2014 17:05 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SERIAL-TFT-M..> 15-Jul-2014 17:05 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TMR-2-series..> 15-Jul-2014 16:48 787K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-DC-DC-Conver..> 15-Jul-2014 16:48 781K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Full-Datashe..> 15-Jul-2014 16:47 803K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TMLM-Series-..> 15-Jul-2014 16:47 810K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TEL-5-Series..> 15-Jul-2014 16:47 814K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TXL-series-t..> 15-Jul-2014 16:47 829K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TEP-150WI-Se..> 15-Jul-2014 16:47 837K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AC-DC-Power-..> 15-Jul-2014 16:47 845K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TIS-Instruct..> 15-Jul-2014 16:47 845K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TOS-tracopow..> 15-Jul-2014 16:47 852K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TCL-DC-traco..> 15-Jul-2014 16:46 858K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TIS-series-t..> 15-Jul-2014 16:46 875K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TMR-2-Series..> 15-Jul-2014 16:46 897K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TMR-3-WI-Ser..> 15-Jul-2014 16:46 939K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TEN-8-WI-Ser..> 15-Jul-2014 16:46 939K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SOURIAU-Cont..> 08-Jul-2014 19:04 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-T672-3000-Se..> 08-Jul-2014 18:59 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-tesa®pack63..> 08-Jul-2014 18:56 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Encodeur-USB..> 08-Jul-2014 18:56 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CC2530ZDK-Us..> 08-Jul-2014 18:55 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-2020-Manuel-..> 08-Jul-2014 18:55 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Synchronous-..> 08-Jul-2014 18:54 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Arithmetic-L..> 08-Jul-2014 18:54 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NA555-NE555-..> 08-Jul-2014 18:53 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-4-Bit-Magnit..> 08-Jul-2014 18:53 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LM555-Timer-..> 08-Jul-2014 18:53 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L293d-Texas-..> 08-Jul-2014 18:53 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SN54HC244-SN..> 08-Jul-2014 18:52 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MAX232-MAX23..> 08-Jul-2014 18:52 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-High-precisi..> 08-Jul-2014 18:51 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SMU-Instrume..> 08-Jul-2014 18:51 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-900-Series-B..> 08-Jul-2014 18:50 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BA-Series-Oh..> 08-Jul-2014 18:50 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-UTS-Series-S..> 08-Jul-2014 18:49 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-270-Series-O..> 08-Jul-2014 18:49 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-UTS-Series-S..> 08-Jul-2014 18:49 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Tiva-C-Serie..> 08-Jul-2014 18:49 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-UTO-Souriau-..> 08-Jul-2014 18:48 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Clipper-Seri..> 08-Jul-2014 18:48 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-851-Series-P..> 08-Jul-2014 18:47 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-HIP4081A-Int..> 07-Jul-2014 19:47 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ISL6251-ISL6..> 07-Jul-2014 19:47 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-DG411-DG412-..> 07-Jul-2014 19:47 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-3367-ARALDIT..> 07-Jul-2014 19:46 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ICM7228-Inte..> 07-Jul-2014 19:46 1.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Data-Sheet-K..> 07-Jul-2014 19:46 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Silica-Gel-M..> 07-Jul-2014 19:46 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TKC2-Dusters..> 07-Jul-2014 19:46 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CRC-HANDCLEA..> 07-Jul-2014 19:46 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-760G-French-..> 07-Jul-2014 19:45 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Decapant-KF-..> 07-Jul-2014 19:45 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-1734-ARALDIT..> 07-Jul-2014 19:45 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Araldite-Fus..> 07-Jul-2014 19:45 1.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-fiche-de-don..> 07-Jul-2014 19:44 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-safety-data-..> 07-Jul-2014 19:44 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-A-4-Hardener..> 07-Jul-2014 19:44 1.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CC-Debugger-..> 07-Jul-2014 19:44 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SmartRF06-Ev..> 07-Jul-2014 19:43 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CC2531-USB-H..> 07-Jul-2014 19:43 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Alimentation..> 07-Jul-2014 19:43 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BK889B-PONT-..> 07-Jul-2014 19:42 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-User-Guide-M..> 07-Jul-2014 19:41 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SL59830-Inte..> 06-Jul-2014 10:11 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ALF1210-PDF.htm 06-Jul-2014 10:06 4.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD7171-16-Bi..> 06-Jul-2014 10:06 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Low-Noise-24..> 06-Jul-2014 10:05 1.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ESCON-Featur..> 06-Jul-2014 10:05 938K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-74LCX573-Fai..> 06-Jul-2014 10:05 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-1N4148WS-Fai..> 06-Jul-2014 10:04 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-FAN6756-Fair..> 06-Jul-2014 10:04 850K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Datasheet-Fa..> 06-Jul-2014 10:04 861K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ES1F-ES1J-fi..> 06-Jul-2014 10:04 867K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-QRE1113-Fair..> 06-Jul-2014 10:03 879K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-2N7002DW-Fai..> 06-Jul-2014 10:03 886K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-FDC2512-Fair..> 06-Jul-2014 10:03 886K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-FDV301N-Digi..> 06-Jul-2014 10:03 886K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-S1A-Fairchil..> 06-Jul-2014 10:03 896K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BAV99-Fairch..> 06-Jul-2014 10:03 896K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-74AC00-74ACT..> 06-Jul-2014 10:03 911K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NaPiOn-Panas..> 06-Jul-2014 10:02 911K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LQ-RELAYS-AL..> 06-Jul-2014 10:02 924K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ev-relays-ae..> 06-Jul-2014 10:02 926K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ESCON-Featur..> 06-Jul-2014 10:02 931K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Amplifier-In..> 06-Jul-2014 10:02 940K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Serial-File-..> 06-Jul-2014 10:02 941K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Both-the-Del..> 06-Jul-2014 10:01 948K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Videk-PDF.htm 06-Jul-2014 10:01 948K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-EPCOS-173438..> 04-Jul-2014 10:43 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Sensorless-C..> 04-Jul-2014 10:42 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-197.31-KB-Te..> 04-Jul-2014 10:42 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PIC12F609-61..> 04-Jul-2014 10:41 3.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PADO-semi-au..> 04-Jul-2014 10:41 3.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-03-iec-runds..> 04-Jul-2014 10:40 3.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ACC-Silicone..> 04-Jul-2014 10:40 3.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Series-TDS10..> 04-Jul-2014 10:39 4.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Q48-PDF.htm 23-Jun-2014 10:29 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-15..> 23-Jun-2014 10:29 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BZX384-serie..> 23-Jun-2014 10:29 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AN10361-Phil..> 23-Jun-2014 10:29 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-KSZ8851SNL-S..> 23-Jun-2014 10:28 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BF545A-BF545..> 23-Jun-2014 10:28 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PIC18F2455-2..> 23-Jun-2014 10:27 3.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PMBT4403-PNP..> 23-Jun-2014 10:27 3.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-24AA024-24LC..> 23-Jun-2014 10:26 3.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Leaded-Trans..> 23-Jun-2014 10:26 3.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SSC7102-Micr..> 23-Jun-2014 10:25 3.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Fastrack-Sup..> 23-Jun-2014 10:25 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BC847DS-NXP-..> 23-Jun-2014 10:24 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-HI-70300-Sol..> 14-Jun-2014 18:27 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Davum-TMC-PD..> 14-Jun-2014 18:27 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Repartiteurs..> 14-Jun-2014 18:26 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Documentatio..> 14-Jun-2014 18:26 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Fiche-de-don..> 14-Jun-2014 18:26 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SPLC780A1-16..> 14-Jun-2014 18:25 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Construction..> 14-Jun-2014 18:25 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Alimentation..> 14-Jun-2014 18:24 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-C.A-6150-C.A..> 14-Jun-2014 18:24 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Fluke-1730-E..> 14-Jun-2014 18:23 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Ponts-RLC-po..> 14-Jun-2014 18:23 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Serie-Standa..> 14-Jun-2014 18:23 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-FDS-ITW-Spra..> 14-Jun-2014 18:22 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-HFE1600-Data..> 14-Jun-2014 18:22 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TDK-Lambda-H..> 14-Jun-2014 18:21 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-HC49-4H-Crys..> 14-Jun-2014 18:20 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Avvertenze-e..> 14-Jun-2014 18:20 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Ceramic-tran..> 14-Jun-2014 18:19 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ADL6507-PDF.htm 14-Jun-2014 18:19 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PMEG4002EL-N..> 14-Jun-2014 18:18 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Midas-Active..> 14-Jun-2014 18:17 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Molex-83421-..> 14-Jun-2014 18:17 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Molex-COMMER..> 14-Jun-2014 18:16 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-10TPB47M-End..> 14-Jun-2014 18:16 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-U2270B-PDF.htm 14-Jun-2014 18:15 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SVPE-series-..> 14-Jun-2014 18:15 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-F28069-Picco..> 14-Jun-2014 18:14 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Termometros-..> 14-Jun-2014 18:14 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Cordless-dri..> 14-Jun-2014 18:13 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Battery-GBA-..> 14-Jun-2014 18:13 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CD4536B-Type..> 14-Jun-2014 18:13 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-0430300011-D..> 14-Jun-2014 18:13 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Mistral-PDF.htm 14-Jun-2014 18:12 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Connectors-N..> 14-Jun-2014 18:12 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-XPS-AC-Octop..> 14-Jun-2014 18:11 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Midas-MCCOG4..> 14-Jun-2014 18:11 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-V4N-PDF.htm 14-Jun-2014 18:11 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Signal-PCB-R..> 14-Jun-2014 18:11 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PIC24FJ256GB..> 14-Jun-2014 09:51 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-DC-Fan-type-..> 14-Jun-2014 09:51 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-12mm-Size-In..> 14-Jun-2014 09:50 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-10BQ060-PDF.htm 14-Jun-2014 09:50 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-An-Improved-..> 14-Jun-2014 09:49 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ATmega640-VA..> 14-Jun-2014 09:49 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LME49725-Pow..> 14-Jun-2014 09:49 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Produit-3430..> 14-Jun-2014 09:48 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-USB-Buccanee..> 14-Jun-2014 09:48 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-DC-Fan-type-..> 14-Jun-2014 09:48 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Fiche-de-don..> 14-Jun-2014 09:47 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Nilï¬-sk-E-..> 14-Jun-2014 09:47 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MX670-MX675-..> 14-Jun-2014 09:46 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Tektronix-AC..> 13-Jun-2014 18:44 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PMBT3906-PNP..> 13-Jun-2014 18:44 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PESD5V0F1BL-..> 13-Jun-2014 18:43 1.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PMEG4010CEH-..> 13-Jun-2014 18:43 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PESD9X5.0L-P..> 13-Jun-2014 18:43 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BTA204-800C-..> 13-Jun-2014 18:42 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BYV29F-600-N..> 13-Jun-2014 18:42 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Low-cost-Enc..> 13-Jun-2014 18:42 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BC846DS-NXP-..> 13-Jun-2014 18:42 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-IP4252CZ16-8..> 13-Jun-2014 18:41 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BUJD203AX-NX..> 13-Jun-2014 18:41 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Download-dat..> 13-Jun-2014 18:40 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BT151-650R-N..> 13-Jun-2014 18:40 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-OXPCIE958-FB..> 13-Jun-2014 18:40 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ATtiny26-L-A..> 13-Jun-2014 18:40 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Microchip-MC..> 13-Jun-2014 18:27 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Pompes-Charg..> 24-Apr-2014 20:23 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Alimentation..> 01-Apr-2014 07:42 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-C.A 8332B-C...> 01-Apr-2014 07:40 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ALF1225-12-V..> 01-Apr-2014 07:40 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CS5532-34-BS..> 01-Apr-2014 07:39 3.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ALF2412-24-V..> 01-Apr-2014 07:39 3.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Sefram-GUIDE_SIMPLIF..> 29-Mar-2014 11:46 422K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Sefram-CAT_ENREGISTR..> 29-Mar-2014 11:46 461K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Sefram-SP270.pdf-PDF..> 29-Mar-2014 11:46 464K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Sefram-7866HD.pdf-PD..> 29-Mar-2014 11:46 472K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Sefram-GUIDE_SIMPLIF..> 29-Mar-2014 11:46 481K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Sefram-CAT_MESUREURS..> 29-Mar-2014 11:46 435K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Sefram-GUIDE_SIMPLIF..> 29-Mar-2014 11:46 442K

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Portable-Ana..> 29-Mar-2014 11:16 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CC2560-Bluet..> 29-Mar-2014 11:14 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Ferric-Chlor..> 29-Mar-2014 11:14 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MCF532x-7x-E..> 29-Mar-2014 11:14 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-A-True-Syste..> 29-Mar-2014 11:13 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ELMA-PDF.htm 29-Mar-2014 11:13 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SMBJ-Transil..> 29-Mar-2014 11:12 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-6517b-Electr..> 29-Mar-2014 11:12 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Amplificateu..> 29-Mar-2014 11:11 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ir1150s_fr.p..> 29-Mar-2014 11:11 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-De-la-puissa..> 29-Mar-2014 11:10 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BK2650A-BK26..> 29-Mar-2014 11:10 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Lubrifiant-a..> 26-Mar-2014 18:00 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Circuit-Note..> 26-Mar-2014 18:00 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Circuit-Note..> 26-Mar-2014 18:00 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Current-Tran..> 26-Mar-2014 17:59 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Current-Tran..> 26-Mar-2014 17:59 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Current-Tran..> 26-Mar-2014 17:58 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Current-Tran..> 26-Mar-2014 17:58 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Supercapacit..> 26-Mar-2014 17:57 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-GALVA-MAT-Re..> 26-Mar-2014 17:57 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-GALVA-A-FROI..> 26-Mar-2014 17:56 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-1907-2006-PD..> 26-Mar-2014 17:56 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ARALDITE-CW-..> 26-Mar-2014 17:56 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-06-6544-8-PD..> 26-Mar-2014 17:56 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Miniature-Ci..> 26-Mar-2014 17:55 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ARADUR-HY-13..> 26-Mar-2014 17:55 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LOCTITE-3463..> 25-Mar-2014 08:19 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LCW-CQ7P.CC-..> 25-Mar-2014 08:19 3.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ATtiny20-PDF..> 25-Mar-2014 08:19 3.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-3M-VolitionT..> 25-Mar-2014 08:18 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-EMC1182-PDF.htm 25-Mar-2014 08:17 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MC3510-PDF.htm 25-Mar-2014 08:17 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Directive-re..> 25-Mar-2014 08:16 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Loctite3455-..> 25-Mar-2014 08:16 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LOCTITE-542-..> 25-Mar-2014 08:15 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-5910-PDF.htm 25-Mar-2014 08:15 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-china_rohs_o..> 21-Mar-2014 10:04 3.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Cles-electro..> 21-Mar-2014 08:13 3.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ARALDITE-201..> 21-Mar-2014 08:12 3.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Premier-Farn..> 21-Mar-2014 08:11 3.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-celpac-SUL84..> 21-Mar-2014 08:11 3.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-S-TRI-SWT860..> 21-Mar-2014 08:11 3.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-3M-Polyimide..> 21-Mar-2014 08:09 3.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Strangkuhlko..> 21-Mar-2014 08:09 3.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Reglement-RE..> 21-Mar-2014 08:08 3.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-techfirst_se..> 21-Mar-2014 08:08 3.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Septembre-20..> 20-Mar-2014 17:46 3.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Telemetres-l..> 20-Mar-2014 17:46 3.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Multi-Functi..> 20-Mar-2014 17:38 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-testo-470-Fo..> 20-Mar-2014 17:38 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Novembre-201..> 20-Mar-2014 17:38 3.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-testo-205-20..> 20-Mar-2014 17:37 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-Ra..> 20-Mar-2014 17:37 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-Ne..> 20-Mar-2014 17:36 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-EC..> 20-Mar-2014 17:36 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-Id..> 20-Mar-2014 17:35 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-cree-Xlamp-X..> 20-Mar-2014 17:35 2.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-cree-Xlamp-X..> 20-Mar-2014 17:34 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ADSP-21362-A..> 20-Mar-2014 17:34 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-AD524-PDF.htm 20-Mar-2014 17:33 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MPXV7002-Rev..> 20-Mar-2014 17:33 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-cree-Xlamp-m..> 20-Mar-2014 17:32 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-cree-Xlamp-m..> 20-Mar-2014 17:32 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-50A-High-Pow..> 20-Mar-2014 17:31 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-cree-Xlamp-X..> 20-Mar-2014 17:31 2.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Series-2600B..> 20-Mar-2014 17:30 3.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ECO-Series-T..> 20-Mar-2014 08:14 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PDTA143X-ser..> 20-Mar-2014 08:12 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-TS..> 20-Mar-2014 08:12 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Radial-Lead-..> 20-Mar-2014 08:12 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-GN-RELAYS-AG..> 20-Mar-2014 08:11 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-Y3..> 20-Mar-2014 08:11 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Panasonic-EZ..> 20-Mar-2014 08:10 2.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ATMEL-8-bit-..> 19-Mar-2014 18:04 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-USB1T11A-PDF..> 19-Mar-2014 18:03 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-OSLON-SSL-Ce..> 19-Mar-2014 18:03 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Atmel-ATmega..> 19-Mar-2014 18:03 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-PBSS5160T-60..> 19-Mar-2014 18:03 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MICROCHIP-PI..> 19-Mar-2014 18:02 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Ed.081002-DA..> 19-Mar-2014 18:02 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Instructions..> 19-Mar-2014 18:01 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Serie-PicoSc..> 19-Mar-2014 18:01 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-F42202-PDF.htm 19-Mar-2014 18:00 2.5M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-propose-plus..> 11-Mar-2014 08:19 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Haute-vitess..> 11-Mar-2014 08:17 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Controle-de-..> 11-Mar-2014 08:16 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-TEA1703T..> 11-Mar-2014 08:15 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-XPS-MC16-XPS..> 11-Mar-2014 08:15 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MC21605-PDF.htm 11-Mar-2014 08:14 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-WetTantalum-..> 11-Mar-2014 08:14 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ES2333-PDF.htm 11-Mar-2014 08:14 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SB175-Connec..> 11-Mar-2014 08:14 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Cannon-ZD-PD..> 11-Mar-2014 08:13 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-YAGEO-DATA-S..> 11-Mar-2014 08:13 2.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ATMEL-8-bit-..> 11-Mar-2014 07:55 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-PCA9555 ..> 11-Mar-2014 07:54 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MICREL-KSZ88..> 11-Mar-2014 07:54 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Microship-PI..> 11-Mar-2014 07:53 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-EPCOS-Sample..> 11-Mar-2014 07:53 2.2M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-BT136-60..> 11-Mar-2014 07:52 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NTE_SEMICOND..> 11-Mar-2014 07:52 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-L-efficacite..> 11-Mar-2014 07:52 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-LUXEON-Guide..> 11-Mar-2014 07:52 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Realiser-un-..> 11-Mar-2014 07:51 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-SOT-23-Multi..> 11-Mar-2014 07:51 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-ZigBee-ou-le..> 11-Mar-2014 07:50 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Les-derniers..> 11-Mar-2014 07:50 2.3M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Conception-d..> 11-Mar-2014 07:49 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Puissance-ut..> 11-Mar-2014 07:49 2.4M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MOLEX-43160-..> 10-Mar-2014 17:21 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MOLEX-87439-..> 10-Mar-2014 17:21 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MOLEX-43020-..> 10-Mar-2014 17:21 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-PBSS9110..> 10-Mar-2014 17:21 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-TEKTRONIX-DP..> 10-Mar-2014 17:20 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-uC-OS-III-Br..> 10-Mar-2014 17:20 2.0M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-CIRRUS-LOGIC..> 10-Mar-2014 17:20 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-PSMN7R0-..> 10-Mar-2014 17:19 2.1M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-MOLEX-39-00-..> 10-Mar-2014 17:19 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-manual-bus-p..> 10-Mar-2014 16:29 1.9M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Molex-Crimp-..> 10-Mar-2014 16:27 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-The-essentia..> 10-Mar-2014 16:27 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-OMRON-Master..> 10-Mar-2014 16:26 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Proskit-SS-3..> 10-Mar-2014 16:26 1.8M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-BYV79E-serie..> 10-Mar-2014 16:19 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-74VHC126..> 10-Mar-2014 16:17 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-PSMN1R7-..> 10-Mar-2014 16:17 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-FICHE-DE-DON..> 10-Mar-2014 16:17 1.6M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-HUNTSMAN-Adv..> 10-Mar-2014 16:17 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-NXP-PMBFJ620..> 10-Mar-2014 16:16 1.7M

![[TXT]](http://www.audentia-gestion.fr/icons/text.gif)

Farnell-Pico-Spox-Wi..> 10-Mar-2014 16:16 1.7M

Summary

This white paper addresses the energy consumption of DRAM in computing applications and the

opportunities to maximize energy savings by targeting more efficient products for data center servers.

Micron estimates module power savings at 24 percent; this has the potential to achieve energy savings

of 5.5 billion kilowatt hours (kWh) on a global basis annually. At typical industrial power costs1 ($0.06

per kWh), the savings are more than $300 million per year.

Michael Sporer

Regional Sales Manager, Micron Memory Products Group

©2008 Micron Technology, Inc. All rights reserved 1

The power demands of data centers require memory innovationsThe power demands of data centers require memory innovations

Introduction

The U.S. EPA Energy Star program is conducting a study to assess opportunities for energy efficiency

improvements to computer servers and data centers2. This is in response to Public Law 109-431, which

was passed and signed into law December 20, 20063. This legislation requires an investigation down to

the microchip level. As a manufacturer of semiconductor memory products used in server systems, Micron

intends to proactively address these opportunities.

Justification

A recent study conducted by Dr. Jonathan Koomey4 with the Lawrence Berkeley National Laboratory (LBL)

and funded by Advanced Micro Devices (AMD), illustrated the significant and growing energy use by

data centers. Data centers are rooms, floors or sometimes entire buildings that house computer, storage,

and networking equipment. Data centers can serve up Web pages, stream media, enable Internet access,

and run simulations of any kind of research. They can also provide computing power for traditional and

private uses like banking or other financial transactions.

The computers in data centers, called servers, are similar to PCs in that they have the same basic

microchips—the CPU and memory. Unlike PCs, servers in data centers are packed together as densely

as possible and use substantial amounts of electricity, the majority of which ends up in the form of heat,

which then must be removed from the servers. The power delivery to the systems is provided through

uninterruptible power supplies (UPS) that are not 100 percent efficient and also produce copious amounts

of heat as well. The heat must be carefully and continuously managed to keep the systems running within

their specified operating temperature and humidity ranges. Regardless of the type and efficiency of the

cooling system, the heat must be removed from the data center in one way or another. To do so requires

additional energy be used to operate the cooling infrastructure.

©2008 Micron Technology, Inc. All rights reserved 2

The data centers’ incremental

overhead power consumption

due to inefficiencies and

cooling is estimated to be

equal to the amount that is

consumed by servers, storage,

and networkingIntroduction

The data centers’ incremental overhead power consumption due to inefficiencies and cooling is estimated

to be equal to the amount that is consumed by servers, storage, and networking. The user of a single PC,

workstation, or laptop doesn’t see system heat generation ias a concern, but for data centers, managing

the overhead is as important as the servers themselves. If system power is reduced, then the available

overhead can handle a greater IT load and perform more useful work in the same power envelope.

The Role Memory Plays in the Challenges of Servers and Energy Use

The memory content in servers has been growing at a rapid pace and is expected to continue to do so

for a variety of reasons. In general, software with more functionality requires both greater computational

ability as well as a larger memory footprint. However, some factors are more applicable to servers than

PCs.

First is the proliferation of multi-core CPUs executing single-threaded applications. Each thread requires

its own memory space, therefore doubling the number of CPU cores requires doubling the memory. A

recent seminar5 on server design cited this rule of thumb:

1GB per (1 GHz × # cores)

This equation reinforces the idea that each CPU core mandates an increase in memory space. Another

factor driving memory content growth and server power consumption is the adoption of virtualization

technologies. A server running a virtualized environment is able to achieve a higher utilization which, in

turn, increases the total power consumption of the server. Once again, the importance of energy efficient

component selection increases. By analogy, a car will burn very little fuel if it isn’t driven. Virtualization, or

anything that increases server operation, is like adding a new driver to the mix. Now the car gets driven

more and energy efficiency becomes a greater concern.

Traditionally, the CPU has been the component that consumes the most power in the system. Improvements

in CPU power consumption now place a greater scrutiny on the other components. Where memory once

played a distant second to CPUs in the ranking of system power consumption, now, in some cases, it

exceeds the power consumption of the CPU.

The power demands of data centers require memory innovations

©2008 Micron Technology, Inc. All rights reserved 3

The memory content in servers

has been growing at a rapid

pace and is expected to

continue to do so for a variety

of reasonsThe power demands of data centers require memory innovations

Energy Efficient Memory Advantages

Micron’s new energy efficient Aspen Memory® product line includes several new products that have a

lower power consumption compared to legacy standard products. These technologies are intended for

use in both client machines—PCs, laptops, workstations—as well as in servers.

The new products are 1Gb-based, DDR2 reduced chip count (RCC) modules; and 1.5V DDR2 FBDIMMs.

The 1.5V DDR2 SDRAM operates at 1.5V instead of 1.8V. The 1Gb-based, DDR2 RCC modules provide the

same memory capacity and performance as a DIMM built using legacy (currently 512Mb) devices, but

use half as many higher density (1Gb) DRAM devices (see Appendix A for product details). The combined

savings of these two technologies is estimated to be 24 percent of the memory DIMM power consumption.

For reasons previously cited, extrapolating the savings to the system level is difficult; instead, we have

directly measured power savings at the power supply input of the server under test.

Under minimum and maximum loading conditions and using commercially available systems, Micron

has measured between 1.5 to 1.8 watts per 2GB DIMM improvement in power consumption when

comparing standard legacy products to 1Gb-based, DDR2 reduced chip count DIMMs.

Measurements made in a lab environment using modified commercial hardware with the adaptations

required to support 1.5V DDR2 on FBDIMMs show power reductions in the 1.5 to 2.0 watts per 4GB 1.5V

DIMM attributed only to the DRAM. Additional power savings could be possible using a low-voltage

advanced memory buffer (AMB) chip, which is also on the FBDIMM.

For the purpose of the analyses that follow, it is necessary to convert these savings into a percentage

basis. We will assume a conservative 24 percent DIMM-level savings for the 1Gb-based, DDR2 RCC

DIMM and 1.5V DDR2 SDRAM.

©2008 Micron Technology, Inc. All rights reserved 4

The combined savings of these

two technologies—1Gbbased,

DDR2 reduced chip

count modules and 1.5V

DDR2 SDRAM devices—is

estimated to be 24 percent

of the memory DIMM power

consumptionThe power demands of data centers require memory innovations

Data Centers and Energy Use

According to Dr. Koomey’s report, data center servers consumed 616 billion kWh worldwide in 2005. The

historical growth rate of this figure has been 15 percent annually from the year 2000 to 2005.

Estimating the power consumption attributed to memory is a difficult challenge. A computer system has

multiple memory sockets that can be fully or partially populated with memory modules, and the memory

module density can also vary. In addition to these physical variations, the portion of power attributed to

memory also depends on the type of workload and memory utilization. Certainly, further study is needed

in this area. For the purpose of this paper we are going to assume memory accounts for 20 percent7 of

the total system power budget in a server. The reader can adjust this assumption

as needed.

Micron has come up with an alternative method for estimating DRAM power consumption (summarized

here; details in Appendix C). This method incorporates analysts’ data to estimate the total DRAM

production in a given year and the DRAM consumption by market segment. This method also makes

assumptions regarding hours of operation as well as system utilization to estimate power consumption

and potential savings. (Figure 2 provides the estimate for calendar year 2008.)

The production of DRAM is quantified in terms of 512Mb equivalent units. For example, a single 1Gb

DRAM is equivalent to two 512Mb devices. First, we divide the market into three categories: server, client,

and other. The client-machine category includes desktops, laptops, and workstations. The other category

is a catch-all for non-computing markets and is not considered in this analysis. Given these market

segments, it’s apparent that the client market consumes four times as many DRAM equivalent units as

the server market.

Next, we consider the hours of operation and system utilization on an annual basis. Servers operate 24

hours a day, 7 days a week; client machines operate approximately 8 hours a day, 5 days a week. Server

utilization is assumed to be 15 percent; client, 5 percent. By applying the usage model to each DRAM

market, we conclude that despite the four-to-one difference in shipments, the DRAM in servers consumes

more power than all DRAM in the client machines.

©2008 Micron Technology, Inc. All rights reserved 5

Estimation of Memory Power

Consumption and Potential Savings

Illustrates the potential savings. For a detailed description, see Appendix B.

2005

61 billion kWh servers

12 billion kWh servers

20%

24%

2.9 billion kWh potential

savings in 2005

34 billion kWh

non-memoryThe power demands of data centers require memory innovations

Next, we consider the total available 1Gb DRAM which could be used to build the 1Gb-based, DDR2 RCC

DIMMs (see Appendix A for RCC details). For 2008, all 1Gb DRAM production is estimated to be enough

to provide for 98 percent of the total demand for servers or 24 percent of the total demand for client

machines. Finally, we look at the potential power savings for all the 1Gb-based, DDR2 RCC DIMMs if they

were installed into either client machines or servers.

When we analyze this power-savings comparison, we see that although the DIMM power requirements

and potential savings are identical in either application, the cumulative energy savings is substantial for

the server market due the longer hours of operation and higher utilization factors of server platforms. In

this example, 462 million kWh energy savings would be achieved for energy efficient DRAM devices sold

this year. This approach would conserve 2.3 billion kWh over a five-year product lifecycle.

©2008 Micron Technology, Inc. All rights reserved 6

Savings in servers are much

greater because, unlike client

machines, servers are always

running

Estimation of power conusmption based on annual

DRAM manufacturing and market usage

13,849 million 512Mb EQ

DRAM produced

1,870 million in servers 7,478 million in

client machines

66MW

potential savings

13MW

potential savings

53MW could be saved by steering all available

1Gb DRAM to servers instead of client machines in 2008

463 million kWh per year

2,314 million kWh potential savings in 2008

9,348 million in servers and

client machines

135MW total power

for all DRAM in servers

109MW total power

for all DRAM

in client machines

67.5%

High use Low use

If all 1Gb went into

servers as RCC

If all 1Gb went into

client machines as RCC

Straight conversion to

kWh annually

Assume 5-year lifecycle; extrapolate

to the entire installed base

20%

Other marketsThe power demands of data centers require memory innovations

Comparing the Two Methods

Let’s attempt to correlate the two estimation methods. First we need to look at the differences so we

can compensate accordingly. The first method is based on data from 2005 and assumes both 1Gb-based,

DDR2 RCC DIMMs and 1.5V devices are placed into the installed base. The second method is based on

data for 2008 and assumes only 1Gb-based, DDR2 RCC DIMMs are used (see figure below).

To extrapolate from 2005 to 2008, we will assume a 15 percent annual growth rate consistent with the

previous five years. As a first approximation we will assume that the savings from 1.5V DDR2 devices

and 1Gb-based, DDR2 RCC modules are equal. As shown below, both methods demonstrate 4.5 billion

kWh annual potential savings for DRAM in servers. The aggregate data center energy savings would

be doubled when considering the incremental overhead and cooling energy costs. Alternately, instead

of reducing power consumption, these savings could be used to support more IT equipment within the

existing infrastructure, resulting in better asset utilization and deferring the need for new data center

construction.

©2008 Micron Technology, Inc. All rights reserved 7

Comparing the Two Methods for Estimating Energy Savings

4.4 billion kWh in 2008 -4.6 billion kWh from both

RCC and 1.5V devices

4.5 billion kWh from both

RCC and 1.5V devices

Savings from overhead roughly equal to IT load;

therefore, 4.5 billion x 2 = -9 billion kWh savings

2.9 billion kWh in 2005

potential saving from RCC and 1.5V devices

2.3 billion kWh in 2008

potential saving from RCC only

Data Center

Use Calculation

DRAM Production

Calculation

Extrapolate to 2008 based on 15%

annual growth historical trend

Reasonable

agreementThe power demands of data centers require memory innovations

Conclusion

This paper brings together three important findings for memory with respect to energy consumption in

computing applications. First, we highlight the growing memory content per server due to the increasing

deployment of multi-core CPUs. We also discuss the relative importance of memory as CPUs and other

sub-assemblies are being optimized for lower energy consumption. Second, we demonstrate two methods